First article inspection

FIRST ARTICLE INSPECTION

Get your PCB assemblies right – the first time, in record time

Speed your way to production of higher quality PCB assemblies with the most efficient first article inspection (FAI) solution available.

The Extra Eye First Article Inspection System helps you ensure your PCB assembly line is producing accurate boards, right from the start, and all the way through your production run. It streamlines every aspect of inspection, from program setup to the inspection process itself. With this easy-to-use, automated FAI system, you can dramatically shorten time-to-production, reduce end-of-line defects and improve yield. Using Extra-Eye, you’ll see lower costs and higher-quality products.

Do more, faster

- Create a new inspection program in less than a minute

- Automatically locate boards in a multi-board panel in seconds

- Locate and inspect multiple identical components with a single click

- Automatically and instantly compare entire boards to the golden board

Do more, easier

- Automate inspection, even for first boards

- Easily view even the smallest components, with automatic rotation and zoom

- Quickly and accurately inspect components added after SMT assembly

- Generate detailed documentation of every inspection

Who needs automated FAI?

Any company that assembles PCBs can gain real, bankable value from automated first article inspection. As one of the most critical steps in PCB assembly setup, FAI can stop a single small mistake from ruining an entire production run.

Extra Eye’s automated First Optical Inspection process is significantly more accurate and faster than manual inspection. With setup in minutes and easy operation, Extra-Eye FAI provides a cost-effective alternative to automatic optical inspection (AOI) for low-volume series.

FAI & AOI

Now Two Systems in One

- Lowest cost camera based system available that does not require a dedicated technician to program or operate.

- Auto inspection achieved within minutes from receipt of basic information, not hours.

- Automatically generates a full report.

Common Features:

- Camera Based system

- Fiducial Correction

- Does not require a dedicated Technician to program or operate

- Professional report generation for full tracability

- SPC output to Excel

- Self teach coordinates if no XY data is available

- Multi-panel with scrap circuit option

FAI: (First Article Inspection)

- Designed to aid True First Article Inspection

- Proven to improve efficiency by up to 70% when compared to traditional methods of manual Inspection

- Brings together the line item from the BOM, image of placed part and drawing reference in a single screen shot

AOI: (Automatic Optical Inspection)

- Verifies Part Number stored Library Images against actual fitted parts: 30 seconds for 1500 components

- Checks for presence, polarity, value, billboard, tombstone, skewed placement

- Choice of algorithm with sensitivity adjustment; OCR or Colour

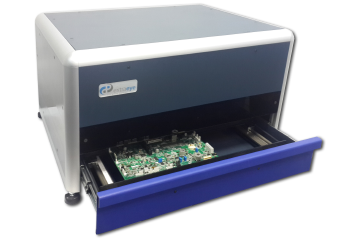

Max PCB size: 380 x 450

Max component height: 50 (mm)

Image resolution: 1100 DPI

Dimensions: 680x575x380 (mm)

Weight: X-Y Axis camera system 24 (kg) 240VAC

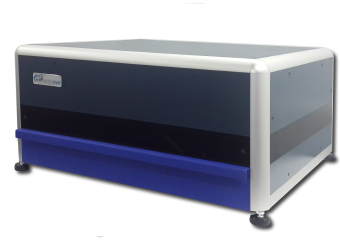

Max PCB size: 500×540 (mm)

Max component height: 50 (mm)

Image resolution: 1100 DPI

Dimensions: 770x730x380 (mm)

Weight: 32 (kg)Window 7+

All rights reserved BIGROTH Ltd. © 2020